Optics Laboratory

ARA’s Littleton, Colorado facility houses an 800-square-foot Laser/Optics Lab, which has been designed for the rapid development of new capabilities and technical maturation of low technical readiness optical and laser-material interaction concepts.

Our state-of-the-art Optics Laboratory, in combination with our highly skilled technical staff, allows us to offer technically excellent, in-depth and diversified research and engineering to provide answers to complex problems.

Research Areas

Optical/Remote Sensing

Phenomenology discovery for long-range detection, characterization of atmospheric aerosols, atmospheric optical propagation, quantum sensing of EM fields, Laser Ionization Breakdown Spectroscopy (LIBS), Raman, multi-spectral imaging/radiometry, microscopy.

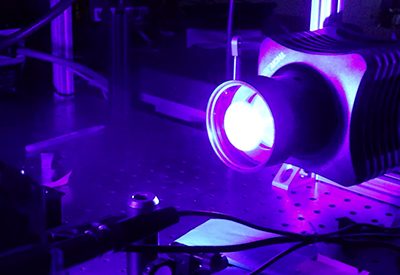

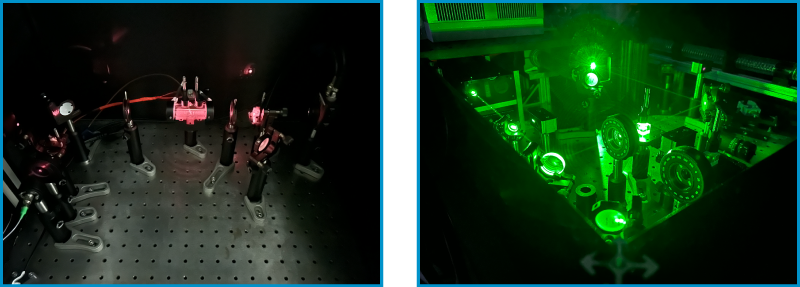

Left: Atomic spectroscopy testbed for advanced electromagnetic field sensing.

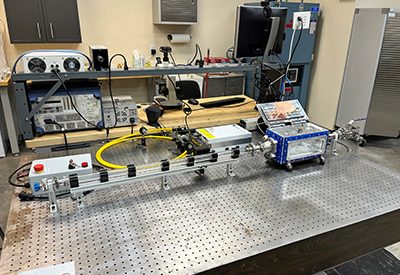

Right: Harmonic wavelength separation configuration for material processing experiments.

Critical Materials

Low hazard domestic production of critical materials, improved domestic supply chains, advanced recycling/separation methods, remote characterization of hazardous effluents.

Laser-Materials Interaction

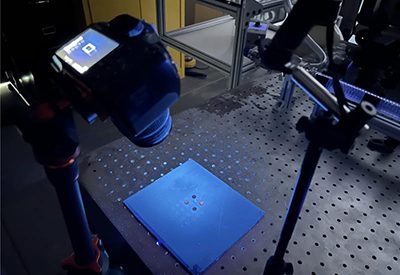

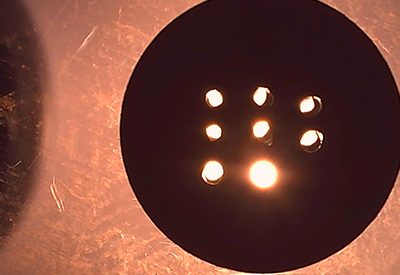

Laser plasma formation, ionization, optical/ion collection diagnostics, enhanced combined pulse laser ablation, optical diagnostics including spectroscopy, thermal measurements, and radiometry.

Laser ablation processing of metals and dielectric materials using different laser parameters.

Energy R&D

Advanced solar technology, photocatalysis, resilient energy systems, off-grid/expeditionary power, reduced logistics burdens, laser structured surface coatings with functional properties.

National Security

Energetic Systems R&D including initiation and optical detonation diagnostics, intermediate force capabilities, chem/bio/rad. sensing, directed energy test and effects.

Opportunities for Collaboration

Adjacent to our Rapid Prototyping Facilities for custom electro-mechanical systems, access to Colorado School of Mines and the University of Colorado-Boulder’s academic shared instrument facilities, including SEM-EDS, XRD, Raman, XRF and other materials characterization/micro-fab facilities.

SAFE AND APPROVED

Capabilities

- Particle concentration and analysis

- Measurement analysis and simulation

- Sample prep

Laser Systems

- Interlocked laser lab with Class IV operation

- Pulsed Nd:YAG (fundamental/SHG/THG)

- High rep-rate fiber machining laser (20 W @ 1060 nm)

- Ultra-narrow tunable laser diode w/ TEC driver (45 mw @780 nm)

- Continuous-wave HeNe laser @ 632.8 nm

Optical Diagnostics

- Spectrometers (VIS-SWIR, to <0.5 nm resolution)

- High speed video (Phantom @ 10 kfps)

- Photodetectors (fast photodiodes, PMT, APD)

- Fiber-optic systems

- Optical power meters

Lab Facilities

- Class I,II and III explosive permits/magazine

- Custom vacuum systems

- Thermal control systems

- Fume hood

- Wet chemistry

- Vacuum oven

- Custom test fixtures

Instrumentation

- High-power LEDs ranging from UV – Near Infrared wavelengths

- Binocular compound microscope w/ 4x, 10x, 40x, and 100x objectives with AmScope digital camera

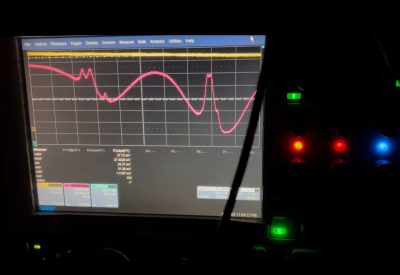

- High speed oscilloscope (3 GHz)