ESCU: Energy Saving Control Unit

Challenge

Considering the high costs, in dollars and in lives, associated with using diesel generators to supply power on deployed military bases, consumption of this energy must be minimized. Reducing energy consumed by Environmental Control Units (ECUs) is an ideal approach to this goal since they were recently shown to comprise nearly 70% of deployed base electricity loads. ECUs currently operate very inefficiently – the supply air fan runs nonstop to ensure warfighters have adequate fresh air. This brute-force approach to warfighter safety and comfort can consume as much as 50% more energy than required. ARA sought to optimize ECU operation so that warfighter safety and comfort are maintained, but at reduced energy consumption.

Solution

After identifying the need to reduce ECU energy consumption, ARA took a fundamental approach and analyzed ECU operation to identify energy loss sources. Once identified, ARA determined the best course of action through extensive brainstorming, analysis of alternatives and other aspects of decision science. We concluded that the best approach was to develop a simple, yet innovative, embedded hardware and software system to eliminate ECU energy losses by modifying its operation.

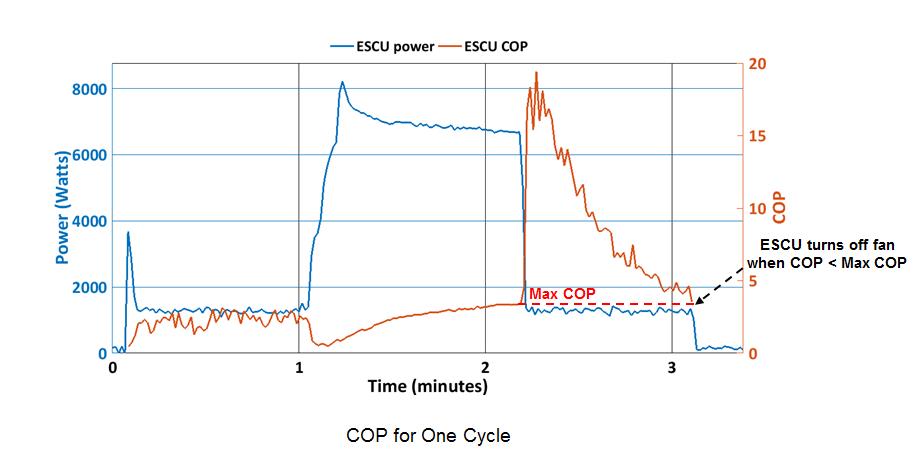

In particular, ARA determined that much of the fan use is being wasted and may even be adversely affecting the shelter environment. ARA mechanical engineers, electrical engineers, chemical engineers, software engineers, and technicians, developed a system to continuously monitor temperature, humidity, CO2 levels, and ECU power consumption, and then adjust ECU operation in such a way that shelter conditions were constantly maintained with reduced energy use. They developed Energy Saving Control Units (ESCUs) that interface with legacy ECUs to reduce their energy consumption while maintaining required safety and comfort levels.

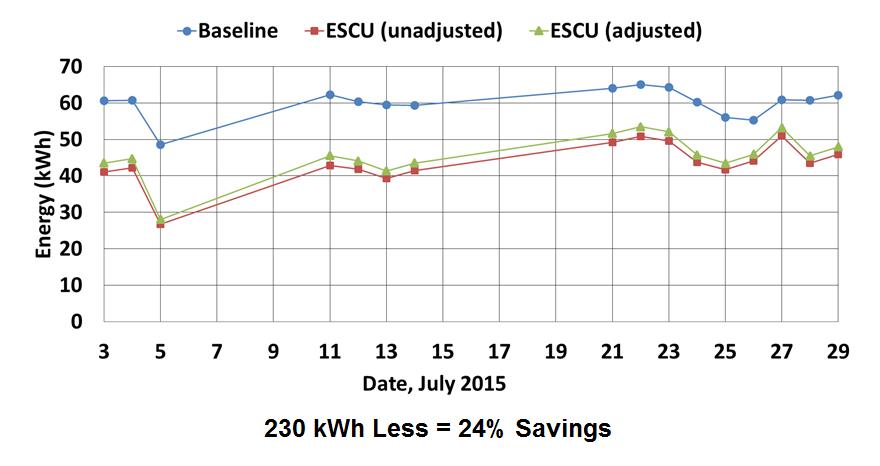

ARA’s cross-functional team leveraged its ability to rapidly move from concept to commercial product to develop a proof-of-concept prototype and a finished product. Extensive testing at Tyndall Air Force Base, FL revealed that on average, ARA’s ESCU technology saved 25% energy daily.