EEEF: Energy-Efficient Expeditionary Flooring

Challenge

Shelters that are lightweight, energy-efficient and easily deployable can help keep logistics and fuel consumption costs to a minimum. ARA developed and demonstrated a lightweight, modular, deployable expeditionary shelter flooring system that incorporates insulated materials and shelter elevation to minimize shelter-to-ground heat transfer—increasing efficiency by reducing the energy needed to heat the shelter. A critical challenge for this effort was to make the system highly transportable by fitting enough flooring for four shelters into a single TRICON container (a specialty container for military transportation), as this placed severe restrictions on the system’s weight and volume.

Solution

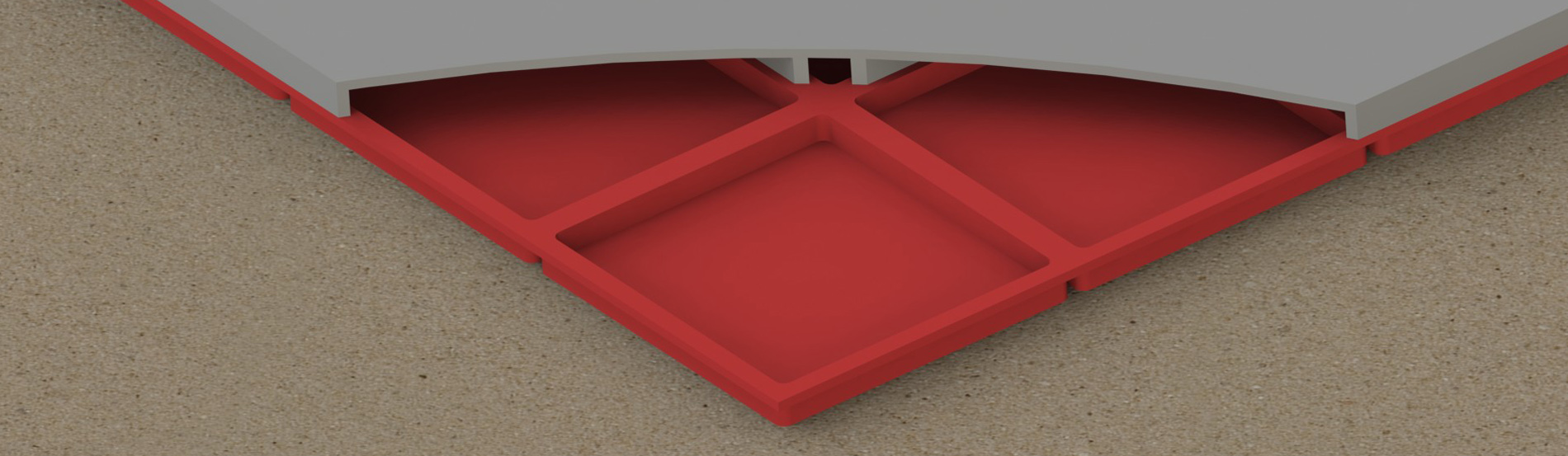

Through brainstorming, evaluation of alternatives, and iterative design and manufacturing processes, ARA developed a unique flooring system that met all of the U.S. Air Force client’s requirements. An advanced design was needed to meet the shipping and height requirements, so ARA created a unique, two-piece panel system where panels nest during storage and stack during deployment. This allows the system to occupy less space during shipping than when deployed.

Once the concept was developed, materials were selected and Finite Element Analysis was used to ensure the system would be capable of sustaining required stress and thermal loads. ARA then collaborated with plastics manufacturers to determine the best production method and used design for manufacture principles to finalize the design.

ARA executed a side-by-side comparison between shelters with and without EEEF and conducted tests to verify the system’s thermal properties. The result: EEEF provides nearly 30 times more insulation than standard shelter floors, resulting in a total energy savings of about 10%.