Hydrothermal Fat Splitting (HFS)

Outperforming Traditional Oil Hydrolysis Methods like colgate-emery

ARA’s Hydrothermal Fat Splitting (HFS) process is a single-step, continuous solution to produce a clean stream of free fatty acids (FFA) and glycerin from a variety of vegetable oils and waste fats, oils, greases. ARA’s HFS process provides a novel alternative to the Colgate-Emery process with a number of distinct advantages.

Hydrothermal Fat Splitting (HFS) Advantages

SEND ME MORE INFORMATION:

For licensing information, contact:

Chuck Red | cred@ara.com | 850-628-0332

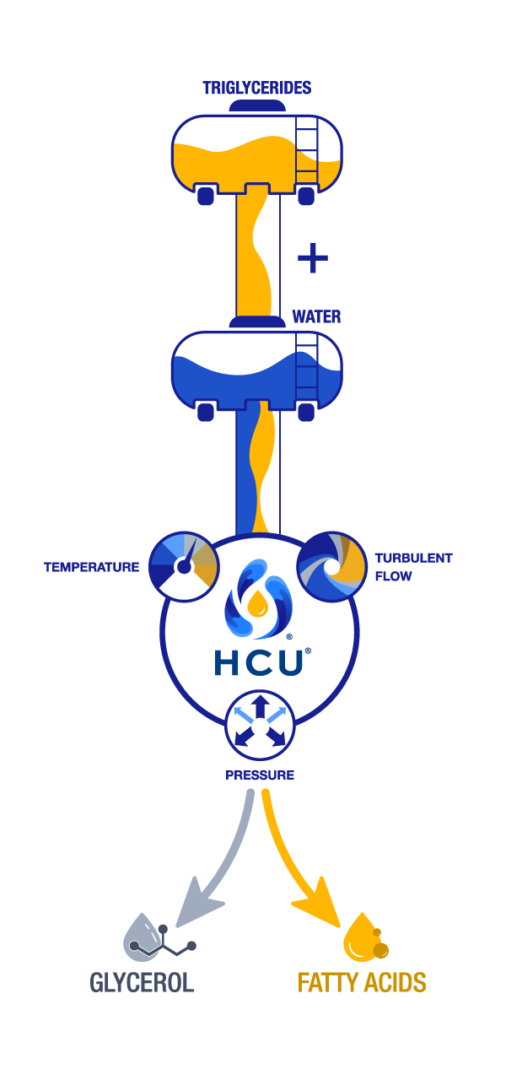

How it Works

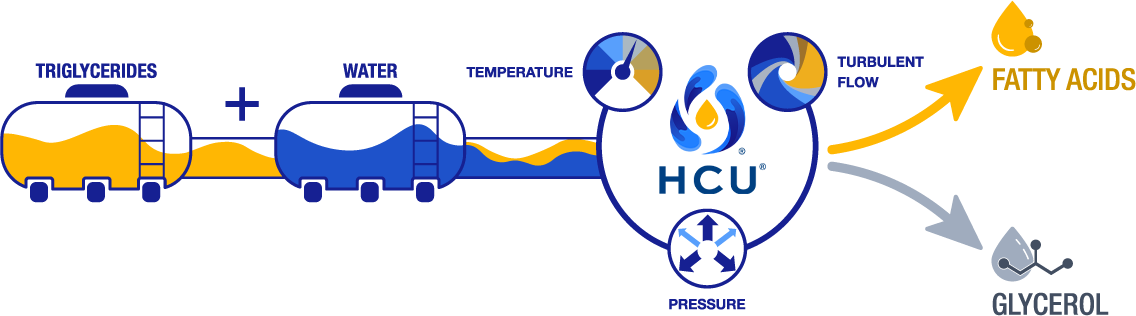

The HFS process utilizes standard equipment such as pumps, heat exchangers, heaters, and oil water separators to split fats and effectively remove phosphorus, chlorides, metals and other inorganics from a variety of fat, oil and grease feedstocks. Oil and water enter the process at turbulent flow with high temperatures and pressure, ensuring the thorough mixing of fats, oils, and greases with water. This rapidly hydrolyzes the lipids to produce clean free fatty acids and glycerin and transfers the contaminants from the fats, oils, and greases to the water.

Traditional fat splitting methods require very clean oil inputs as more contaminated feedstocks produce hard to break oil-water emulsions. HFS allows for the processing of highly contaminated fats, oils, and greases with highly saturated fats, high molecular weight, complex mixtures, and higher viscosities, all in a single step. HFS completely eliminates the need for pretreatment and/or post-treatment washing. This means that using our HFS process maximizes your yield by achieving more than 90% hydrolysis conversion in 1/10th the residence time when compared to the Colgate-Emery method.

Related Technologies

For more information, contact Chuck Red at cred@ara.com

Covered by U.S. Patent 10,071,322 B2 (2018) and European Patent 3250660 (2023)